Smaller is Better!

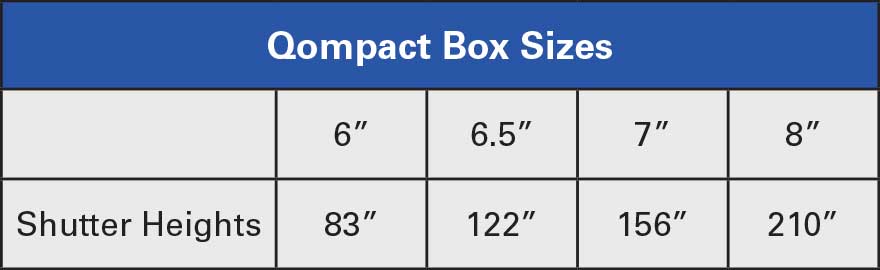

New engineering enables a 13 ft. tall roll shutter to fit into a 7” coil housing, while providing one of the strongest shutters for hurricane protection on the market.

Rolling Shutters in North America need to be smaller to increase public acceptance. The rolling shutter was imported from Europe, but building techniques there hide the boxes inside the walls.

American and Caribbean installations, however, almost always have the shutter housing protruding from the building’s face.

A significant feat in roll shutter technology has just been met with the development of the Qompact shutter system. Protected by patents developed by QMI of Itasca, Illinois, this new system currently includes up to 12 different incrementally larger slat sizes to compose the shutter curtain.Each subsequent slat grouping has a specific radius designed to accommodate the ever-increasing roll diameter.

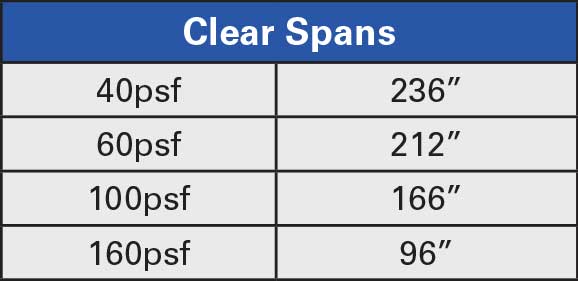

The end result is a shutter system that rarely requires the use of storm bars. The chart (below) shows QMI’s Qompact shutter’s clear spans under the Florida Building Commission (FBC) approvals.

The Qompact shutter is available in widths up to 20’ wide. Installations up to 100psf may be nearly 14’ wide without needing an unsightly storm bar. “The small Qompact coil, the exceptional strength of the single wall slats, plus the rare need for storm bars, gives customers the unrestricted views they desire and makes selling the Qompact shutter very easy,” says Pendleton.

Manual Push up/Pull down operation is available with the Qompact shutter system. Counter balance springs inside the tube make operation nearly effortless. A patented rail spring cushions the shutter when it reaches the top–reducing noise and wear to the shutter. The manual operation is available up to 150 square feet in size.

Most balconies can take advantage of these shutters with the push up/pull down option to save installation cost and to reduce electrical reliance during a storm. Simple mortise slide locks, or optional keyed locks, keep the base slat safely and securely locked.

All of our innovations have reduced warranty service and helped make our dealers more profitable because they can complete the installation in one trip. Our shutters install faster, saving dealers time and money.

The slats perfectly nest with the adjacent roll of slats which provides virtually no wasted space, giving us the tightest roll diameter in the market. A standard patio door roll shutter can now be covered with just a 6.5” coil housing and most windows only require a 6” housing. “Qompact shutters typically have a 40% smaller coil size than almost any other shutter manufacturer

A standard patio door roll shutter can now be covered with just a 6.5” coil housing and most windows only require a 6” housing. “Qompact shutters typically have a 40% smaller coil size than almost any other shutter manufacturer.

QMI designed a hinge for the Qompact system which is also significantly stronger than other roll shutters. The pull-a-part strength of this hinge exceeds 2,600 lbs. The strong hinge is further enhanced with an end retention system using #10 x 2” truss torx 410 stainless steel Dacromet-coated screws with Delrin® shoulder bushings. The retaining screw at each end of every slat creates 4,450 lbs. of pull-out strength per slat.

Additional controls for Qompact also include a low voltage battery controller that is good for shutters sized up to an 8’ patio door. The EZ drive battery controller gives customers push button control for up to 40 operations per charge. There typically is no need for overrides because the shutters operate from a battery. This feature is perfect where there is a high probability of utility outages after a severe storm. QMI’s Qompact system also uses a spring-assisted gear drive for effortless crank operations for shutters up to 80 square feet. Qompact motor operated shutters may come with the additional features of a manual override and radio remote control so they can be connected to a customer’s home automation system.

Fast delivery and correct orders are dealer benefits with a QMI partnership. QMI typically ships standard orders within 10 days of receipt and uses a highly protective packaging system resulting in rare shipping damages. Prior to packaging, however, each QMI shutter is factory assembled with limits set, operation and spring tension verified, and inspected to ensure order correctness and quality prior to packaging.

Qompact shutters have been lifecycle tested to 41.6 years and counting. Both the manual spring and the motorized Qompact shutters have been cycle tested for 15,207 cycles to date. “QMI believes a shutter is only as good as the weakest part,” said Steve Miller, VP of Sales at QMI. “During our 25 years of shutter manufacturing, we have introduced springs, improved the design of the gear system, enhanced corrosion protection- and almost eliminated shipping damage.”